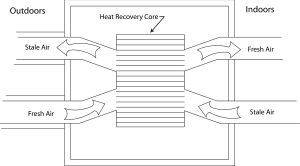

One way to minimize air quality and moisture problems in a home, without opening a window, is by the installation of a mechanical ventilation system such as an air-to-air heat exchanger. An air-to-air heat exchanger brings two air streams of different temperatures into thermal contact, transferring heat from the exhausting inside air to incoming outside air during the heating season.

In summer, the heat exchanger can cool and in some cases, dehumidify the hot outside air passing through it and into the house for ventilation. The air-to-air heat exchanger removes the excess humidity and flushes out odors and pollutants generated indoors.

Types

Generally, heat exchangers are classified by the way the air moves through the unit. In a counter-flow exchanger, hot and cold air streams flow parallel in opposite directions. In a cross-flow unit, the air streams flow perpendicular to each other. An axial flow unit uses a large wheel. The air warms one side of the wheel, which transfers heat to the cold air stream as it slowly turns. A heat pipe unit uses refrigerant to transfer the heat. Other units are available for specialized applications. Small structures, such as houses, generally use counter-flow or cross-flow exchangers.

Heat Recovery Ventilator or Energy Recovery Ventilator and Climate

The majority of air-to-air exchangers installed in northern climates are heat recovery ventilators (HRVs). These units recover heat from exhausted air and return it to the building.

Recent advances in technology have increased the use of energy recovery ventilators (ERVs) as well. In the past, ERVs mainly were used in climates with higher humidity that have a heavier cooling than heating load. The main difference between the two is that HRVs only recover heat, while an ERV will recover heat and humidity. ERVs have had problems with lower efficiencies due to oversaturation of internal desiccant wheels during longer periods of high humidity, but with proper installation and maintenance, they can create a healthier living space and greater energy savings. In addition, the majority of ERVs being sold today are plate-type ERVs that do not contain a desiccant wheel. Consult with a heating/cooling contractor to determine if an HRV or ERV would be most beneficial in your circumstance.

Design

The general design of an air-to-air heat exchanger uses a series of plates, called a core, stacked vertically or horizontally. An ideal plate has high thermal conductivity, high resistance to corrosion, an ability to absorb noises, low cost and low weight. Common plate materials include aluminum, different types of plastic sheets and advanced composites. Originally, heat exchangers used aluminum plates. Problems occurred with corrosion in the damp environment, created by condensation, and poor sound characteristics. Plastics solved the corrosion and some sound problems, but the conductivity did not equal that of the aluminum and the cost was higher. Current high-technology heat exchangers use composite materials meeting all of the criteria.

In addition to the core, the unit consists of an insulated container, defrost controls to prevent moisture freezing on the core and fans to move the air. All heat exchangers need insulation to increase efficiency and reduce condensation formation on the outside of the unit. Different types of defrost mechanisms with sensors within the unit are available to control the defrost process. Fans move air to provide the necessary airflow and ventilation rate.

Counter-flow heat exchangers consist of a core of flat plates. Air enters either end of the exchanger. Heat transfers through the plates to the cooler air. The longer the air runs in the unit, the greater the heat exchange. The percentage of heat recovery is the efficiency of the unit. Efficiencies usually range around 80%. Generally, these units are long, shallow and rectangular, with ducts at either of the long ends.

Cross-flow heat exchangers also use flat plates, but the air flows at right angles. The units have a smaller footprint and may even fit in a window, but lose some of the counter-flow efficiency. Efficiencies typically do not exceed 75%. These units are often cube-shaped with all connections on one face of the cube. The vast majority of heat exchangers used in residential applications use the cross-flow design.

Choices

Choose the model that would best fit your particular needs. Characteristics such as space available for installation, exchange rate needed, and the desired efficiency should be considered. Unfortunately, nearly every manufacturer has different ways of reporting efficiency numbers. For example, ventilation rates depend on the resistance to airflow. A fan with an airflow rate of 150 cubic feet per minute (cfm) actually may produce this flow only at very low pressures. Likewise, a unit may have a stated efficiency of 85%, but may not be better than a unit with an 80% efficiency, depending on the test temperature.

Testing and Comparisons

To standardize manufacturers’ efficiency claims, the Home Ventilating Institute (HVI) tests air-to-air heat exchangers and other ventilation equipment. The tests are used to generate an air-to-air heat exchanger specification sheet. This sheet normalizes exchangers to a given set of pressures and temperatures, enabling efficiencies and airflow rates to be compared across models. The ventilation performance numbers relate the airflow rates to a given pressure, while the energy performance relates a set of given outdoor temperatures to different types of efficiencies. The most important efficiency is the sensible recovery efficiency since most heat exchange occurs during this type of process. The sensible recovery efficiency provides unit efficiencies at specific airflow rates (cfm) and temperatures. These numbers can be compared from one unit to the other to enable proper comparisons at similar airflow rates.

Related Articles

Why is Home Ventilation a Concern

Installation of Air-to-Air Heat Exchanger

Cost Effectiveness of Heat Exchangers

Air-to-Air Heat Exchanger Maintenance